Water Proof Hg Nonwoven Geotextile Machine Non Woven Fabric with CE

1.Introduction:PP spunbond nonwoven fabric and PP meltblown nonwoven fabric are well-known nonwoven fabric in the world.;

Basic Info

| Model NO. | HG-1600/2400/3200 |

| Effective Width | 1600/2400/3200mm |

| Capacity | 5-25 Tons |

| Speed | 100-500m/Min |

| Raw Material | Polypropylene |

| Processing | Nonwoven Fabric |

| GSM | 10-200g/Square Meter |

| Transport Package | Wooden Cases |

| Specification | 20m*8m*11m |

| Trademark | HG NONWOVEN |

| Origin | China |

| HS Code | 8449009000 |

| Production Capacity | 15 Set/Year |

Product Description

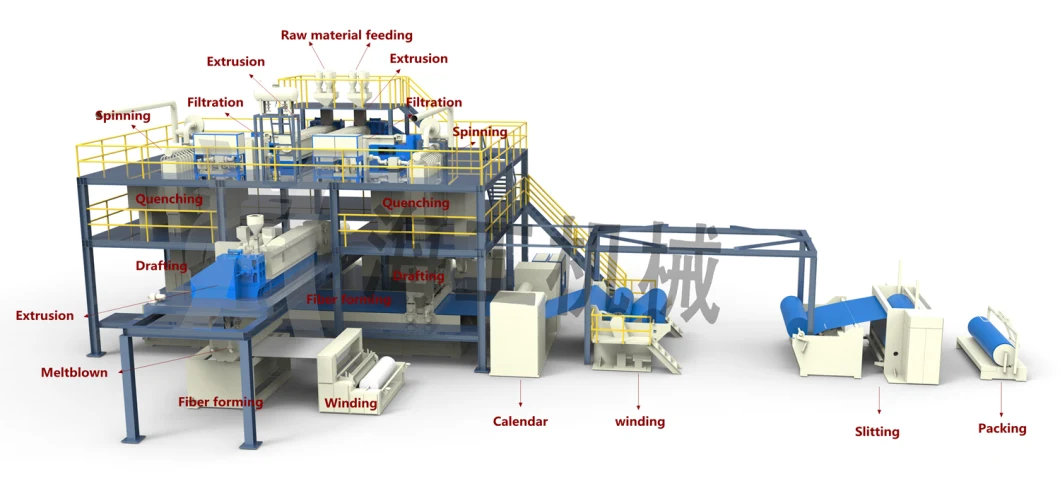

1.Introduction:PP spunbond nonwoven fabric and PP meltblown nonwoven fabric are well-known nonwoven fabric in the world.Both of nonwoven fabric are made by PP(Polypropylene)PP spunbond or meltblown nownoven fabric use different manufacturing process when the production line works.PP spunbond combines fiber spinning with web formation by placing the bonding device in line with spinning.Fibers are former as the molten polymer exits the spinnerets and is quenched by cooling air and deposition on a moving conveyor belt.It is possible to single layer to multi layers nonwove fabric such as S/SS/SSS/SMS/SSMS/SMMS/SSMMS etc...It means one layer fiber splay on another layer again and then thermal bond together.Most of nonwoven fabrics are layered or shingled structure,the number of layers increased with increasing basis weight;High strength-to-weight ratios compared with other woven,and knitted structures.PP Spunbond nonwoven fabric are characterized by tensile,tear,and burst strengths,elongation-to-break,weight,thickness,porosity and stability to heat and chemicals.These properties reflect fabric composition and structure.2.Process flowPP Raw Material→melting and extruding→filtering→metering→spinning→quenching→air-suction→ filament web forming→calendering→winding and slitting→packing→end product.

3.Nonwoven machine details:

| Model | Effective width | Daily capacity | Machine speed | Spinning system | GSM Range | Machine dimensionLength*Width*Height |

| HG-1600M | 1600MM | 2000Kg | 100M/Min | Only meltblown | 10-200grams/m2 | 15*8*8 meter |

| HG-2400M | 2400MM | 3000Kg | 15*10*8 meter | |||

| HG-3200M | 3200MM | 4000Kg | 15*12*8 meter | |||

| HG-1600S | 1600MM | 5000Kg | 200M/Min | Spunbond(S) | 10-200grams/m2 | 20*8*11 meter |

| HG-2400S | 2400MM | 7000Kg | 20*11*11meter | |||

| HG-3200S | 3200MM | 10000Kg | 20*15*11meter | |||

| HG-1600SS | 1600MM | 9000Kg | 350M/Min | Spunbond(SS) | 8-150grams/m2 | 35*10*11meter |

| HG-2400SS | 2400MM | 13000Kg | 35*12*11meter | |||

| HG-3200SS | 3200MM | 16000Kg | 35*15*11meter | |||

| HG-1600SSS | 1600MM | 12000Kg | 400M/Min | Spunbond(SSS) | 8-100grams/m2 | 40*10*11meter |

| HG-2400SSS | 2400MM | 16000Kg | 40*12*11meter | |||

| HG-3200SSS | 3200MM | 23000Kg | 40*15*11meter | |||

| HG-1600SMS | 1600MM | 10000Kg | 400M/Min | Spunbond+Meltblown+Spunbond | 8-80grams/m2 | 40*15*11meter |

| HG-2400SMS | 2400MM | 14000Kg | 40*18*11meter | |||

| HG-3200SMS | 3200MM | 18000Kg | 40*25*11meter | |||

| HG-1600SMMS | 1600MM | 12000Kg | 500M/Min | Spunbond+Meltblown*2+Spunbond | 8-80grams/m2 | 45*15*11meter |

| HG-2400SMMS | 2400MM | 17000Kg | 45*18*11meter | |||

| HG-3200SMMS | 3200MM | 23000Kg | 45*25*11meter |

Advantage of HG Nonwoven Machines:

1.High accurate raw material blender for polyproplyene and additives;2.High capacity extrusion machine with good screw and barrel;3.High performance melt filtration system;4.High Speed with high accurate melt pump;5.Lastest melt flow design and spinning system;6.Well-know PLC control system and motors;7.Smart operation program and monitoring syustem;

4.How important of nonwoven fabric in the worldPP Nonwoven fabric is excellent fabric for application in packing,agriculture,heathcare,medical,hygienic,filtration and so on... because spun bond and meltblown nonwoven fabric can be produced in faster speed with less cost than traditional woven fabric or knitted fabrics.For example,pp spunbond nonwoven fabric is widely used as packaging material where paper products and plastic films are not satisfactory.Most of countries are going to ban plastic bags,so nonwoven fabric bag will be the most popular packing material in the world.The nonwovens for agriculture as crop cover or agriculture protective cover,it is manufactured by spunbond process which polypropylene is spun into fine filaments and bonded,it can be used for a variety of rock gardens,flowerbeds etc.PP nonwoven fabric also has better quality and other application in other field such as health care/hygiene/medical,Modern disposable absorbent hygiene products have made an important contribution to the quality of life and skin health of millions people.Thes user of (i.e. baby diapers,feminine hygiene products and adult incontinence products) benefit from softness,smoothness,leakage prevention,strength and protection provided by pp spunbond and meltblown nonwoven fabric.At the same time medical usage nonwoven fabric plays an important roll as surgical mask/cap/shoes covers for body protection.

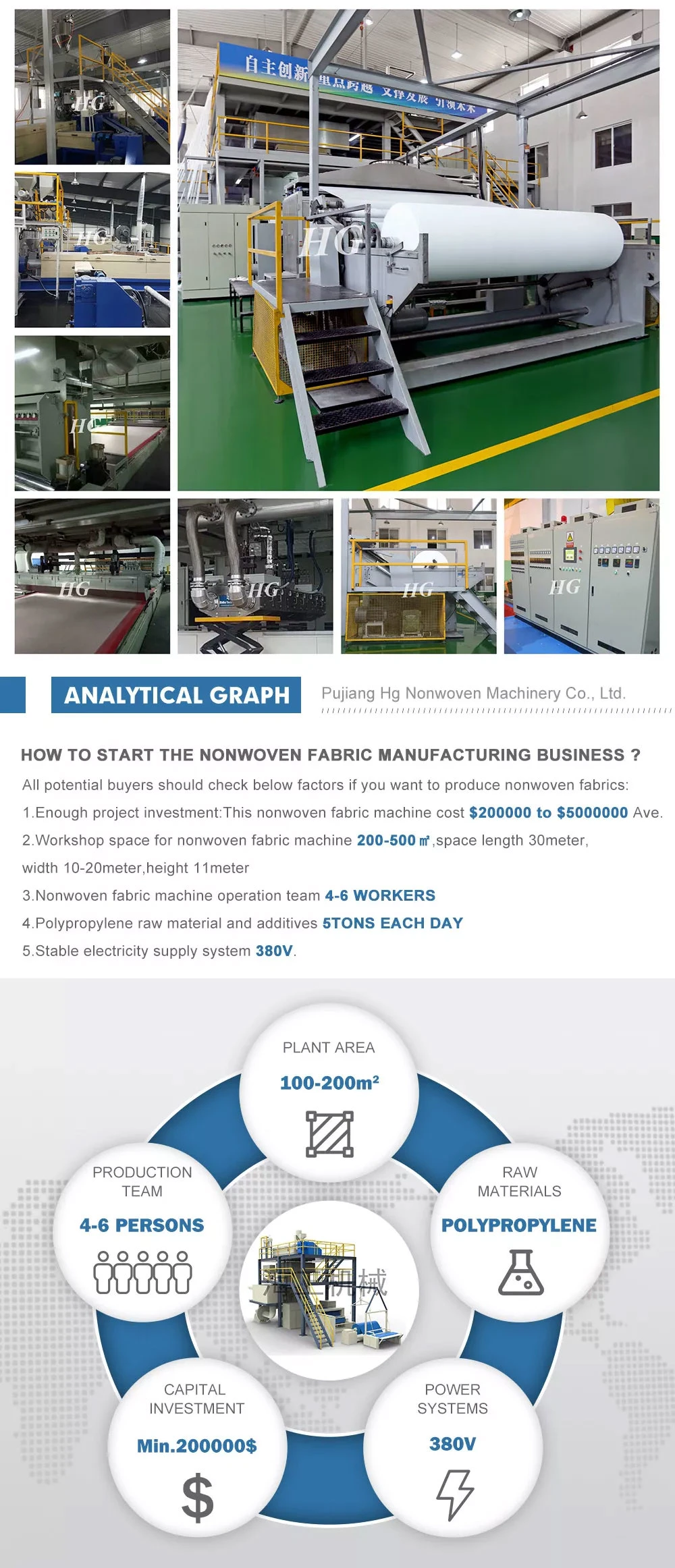

5.Why choose US

1. High standard nonwoven machine specification.2. Free inspection invitation before delivery.3. DUNS&BRADSTREET regiested company;your order safe and your money is safe.4. Free door to door engineering service in 24 month.5. CE Certification and ISO:9001 management system.FAQ:1.How can i know your machine has good quality?You can visit our company and we will see many machines in China,because we also have many customers from local market.2.What is the delivery time for nonwoven machines as usual?We need 3-6 month to make your order.3.Will you inspect my order before shipping?We accept SGS inspection service and buyer own inspect it,we will pay all expense for buyer visiting.4.How is your after-sale service and warranty?we provide 12 month warranty and free door to door engineering service in the period.Free spare parts replacement and online technical support.5.How long time for machine installation?It takes 30-60 days for machine installation as usual.

You may also like

Send inquiry

Send now